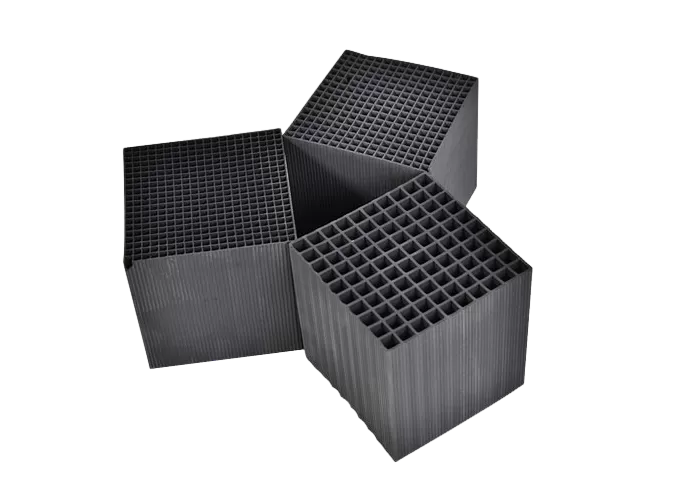

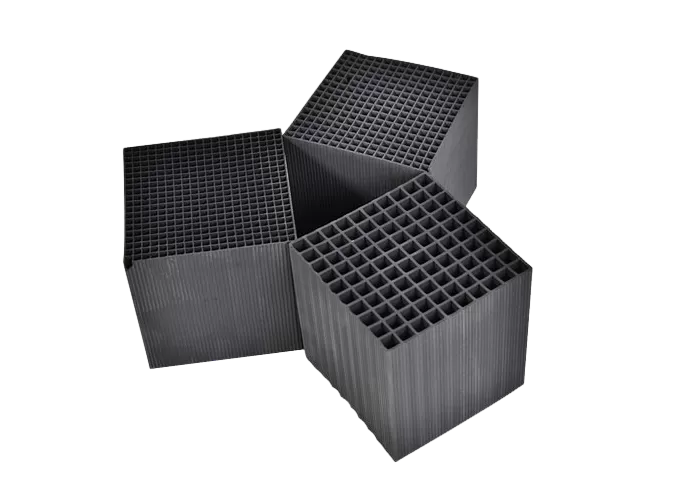

Honeycomb activated carbon

Types, Properties and Applications of Honeycomb Activated Carbon

The main component of honeycomb activated carbon is activated carbon. Its normal compressive strength is greater than 0.8MPa. Common specifications are 5050100mm and 100100100mm. The operating temperature is below 400℃. The pore density is 100 pores per square inch and 150 pores per square inch. The empty tower wind speed is 0.8 meters per second. The specific surface area is greater than 700 square meters per gram. Appearance: The product has a flat surface without cracks. Note: Other specifications can be produced according to user requirements.

There are two types of honeycomb activated carbon: water-resistant and non-water-resistant. All their index parameters are the same, and the specifications can be produced according to customers' requirements. The conventional ones are 100100100mm and 5050100mm. Honeycomb activated carbon is widely used in various organic waste gas purification systems with low concentration and large air volume.

A good method for air pollution control is to use honeycomb activated carbon, which consists of two parallel-connected adsorbers. It can be used to treat both intermittent exhaust and continuous exhaust. One of the adsorbers performs adsorption, while the other undergoes desorption and regeneration. The desorbed pollutants are catalytically burned before being discharged into the atmosphere.

When using honeycomb activated carbon, high temperatures should be avoided as much as possible because high temperatures will reduce the adsorption capacity, and the adsorption effect will decrease with the rise of temperature. At the same time, high dust content in the gas should be avoided, as tar and dust mist will block the fine pores of the activated carbon, increase wind resistance, and reduce the adsorption effect. In such cases, a dust filter device should be installed in front of the honeycomb activated carbon to improve efficiency and service life.

When the exhaust gas to be treated passes through the square pores of the honeycomb activated carbon, it can fully come into contact with the activated carbon, with an adsorption efficiency of up to 67.16%. It has a small wind resistance coefficient, excellent adsorption and desorption performance, and good gas dynamic performance. It can be widely used in the purification of various gases, including organic gases such as toluene, xylene, benzene and other benzene series, phenols, lipids, alcohols, aldehydes, odorous gases, and gases containing trace metals. Environmental protection equipment using honeycomb activated carbon features high purification efficiency in waste gas treatment, a small adsorption bed volume, and low equipment energy consumption, which can reduce the manufacturing cost and operating cost. The purified gas fully meets the environmental protection emission requirements.

Applications of Honeycomb Activated Carbon

It is used in exhaust gas treatment for ventilation equipment in public places such as food industry, chemical industry, industrial exhaust gas treatment, airports, shipyards, electronics industry, automobile factories, pharmaceuticals, medical treatment, industrial buildings, and large theaters.

|

Subject |

Index |

|

|

Specification(mm) |

50*50*100 |

100*100*100 |

|

lodine Absorb(mg/g) |

≥750 |

|

|

Specific Surface Area(m²/g) |

≥600 |

|

|

Carbon tetrachloride(%) |

≥65 |

|

|

Compressive strength(mpa) |

0.9 |

|

|

Moisture(%) |

≤5 |

|

|

Square hole (in)2 |

150 |

|

|

Wall thickness(mm) |

1.0 |

|

|

Temperature(℃) |

≤400 |

|

|

Bulk Density g/cm3 |

0.35-0.60 |

|

|

Adsorption rate of benzene % |

Dynamic adsorption ≥ 37 |

|

|

Adsorption rate of benzene % |

Static adsorption ≥ 52 |

|

|

Empty tower wind speed |

0.8 meters per second |

|

|

Pore density |

100 pores per square inch, 150 pores per square inch |

|

|

Note: All the above specifications and indicators can be produced according to customer requirements. |

||